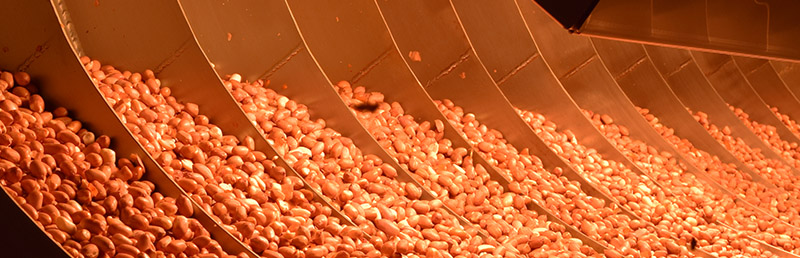

Nuts: sterilisation, roasting, stored products protection, drying, pre-heating and coating using the FoodSafety-IRD.

Nuts, almonds and seeds are very high-quality foodstuff. They are very healthy not least because of their polyunsaturated fatty acids. Nuts contain the water-soluble vitamin B1, which is essential for the metabolism of carbohydrates in the human body. Further constituents are high-quality vegetable proteins, fats, easily usable carbohydrates, fibres, sodium, potassium, calcium, phosphorus, niacin, essential amino acids, fluorine, iron, copper, magnesium, various B vitamins as well as vitamins A, C, D and E. These are added by mineral nutrients and micronutrients such as sugar, linoleic acid, manganese and folic acid.

However, long-chain fatty acids and the volatile or heat-sensitive constituents make these products very sensitive to thermal treatment processes. The fatty acid chains, for example, are easily destroyed especially in roasting processes, which means that the minimum durability of the products will be significantly reduced. They will turn rancid more quickly.

If, however, these products are treated with the innovative KREYENBORG FoodSafety-IRD, the constituents will be protected and the products’ durability will be extended. Owing to the principle of action of the infrared light, the roasted products are heated up from inside and subjected to additional heat input from outside. In this way, a more gentle roasting procedure is achieved and, as a result, homogeneous heat distribution is achieved. The flavour can develop slowly. A mere burning procedure from outside – as it takes place in ordinary convective treatment methods – is thus excluded. The constant mixing of the roasted material facilitates the creation of an absolutely regular roasting result. The product is mixed and conveyed gently, continuously and at low rotational speed. In this way, even brittle products such as cashews, peanuts, almond slivers and the like are treated very gently. Moreover, the roasting time and energy consumption are reduced significantly. There is no more need for any lengthy pre-heating period of the facility.

It is possible to spray in fine water mist during the treatment procedure, if required. In this way, an additional protection of the product is ensured. In the very moment of the surface evaporation of the water sprayed-in, a strong reduction of germs as well as an additional protective effect on the product are achieved due to the re-cooling process. This effect may also be utilized for coating of the nuts e.g. with salt (salt water), for instance.

Incidentally – in the event you should have any problems with harmful insects and / or their oviposition: the most reliable method to kill lively proteins is to heat up the product to roughly 80˚C for a short time. This can be done very quickly using the FoodSafety-IRD.

Moreover, as a pleasant side effect, the risk of formation of salmonella colonies is excluded! Germ reduction could be verified in far more than 8,000 individual analyses, which are carried out by independently accredited laboratories. It has been possible to obtain a successful validation of the 5-log reduction of the microbiological charge and of the safe killing of the ‘comparative salmonella germ’ Enterococcus faecium from independent laboratories.

More Information:

https://www.kreyenborg.com/en/product-detail/foodsafety-ird/

Please contact for further information:

Mr. Wilfried Binternagel

KREYENBORG Plant Technology GmbH & Co. KG

Messingweg 18

48308 Senden

Germany

Phone: +49 2597 93997-151

Fax: +49 2597 93997-60

Mail: w.binternagel@kreyenborg.com