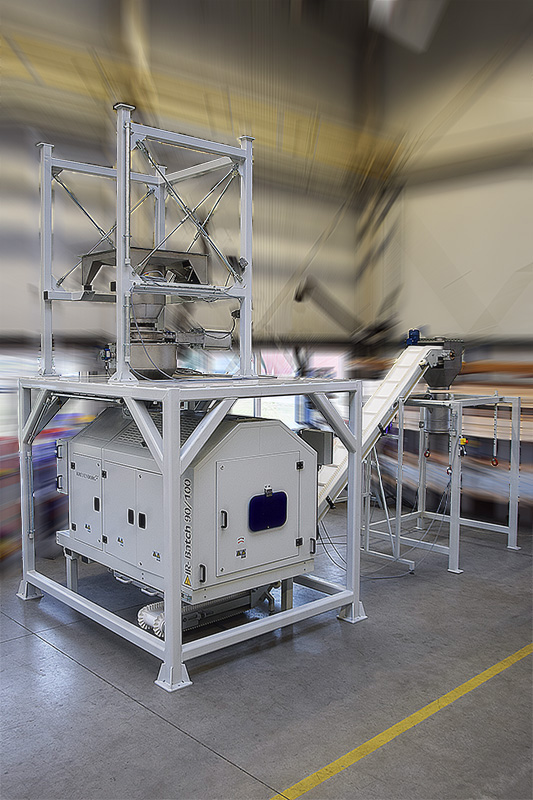

IR BATCH

Discontinuous heating, crystallization, drying and coating of batches of different plastics and other bulk materials in minutes instead of hours.

Heating. Crystallization. Drying.

Areas of application.

Heating. Heating granules and regrind material prior to further processing (e.g. PVC, PE, PP,…) to improve

throughput in the extrusion process.

Crystallization. Crystallization of PET (Bottle flakes, granules, flakes), PET masterbatch, co-PET, PBT, PEEK, PLA, PPS, etc.

Drying. Drying of plastic granules, and ground material (e.g. PET, PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU) as well as other free-flowing bulk materials.

Coating. Coating of adhesives (e.g. Hot melt, EVA+lime,…).

High-input moisture. Drying processes with high input moisture >1%.

Diverse. Heating processes for the removal of rest oligomers and volatile components.

Universal. For use in the plastics, food and chemical industry.

Functions. IRD.

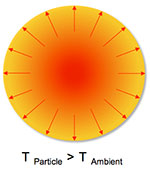

Infrared.

Heat into product core. The energy is instantaneously brought into the core of the product by short-wave infrared radiation.

Inside to the outside. The heat flow pushes the moisture from the inside towards the outside of the product.

Discharge moisture. After the moisture has been released from the material it is directly discharged by the air circulating inside the machine.

Always in motion.

Rotation. The rotation of the drum ensures constant movement of the material.

Evenly. The spiral coils and mixing elements designed for your product ensure an optimal mix of material and avoids clumping. Your product is evenly heated.

Gently. Due to the low rotation speed of the drum there is no dispersion of the material.

Setting. Control.

Retention time. The retention time of the continuous IRD depends on the speed of the rotary drum.

Setting. Retention time, radiation level, and many other process parameters are regulated by means of integrated PLC control.

Control. The process data, such as material and exhaust air temperature or fill levels are continuously monitored by means of sensors and pyrometers. Deviations trigger automatic adjustment.

Reproducibility. Recipes and process parameters can be stored in the controlling system to ensure optimal and reproducible results.

Remote maintenance. Online service via modem.

Radiator module.

Optimized. Our radiator module, developed for the IRD, is thermal- and flow- optimized and is cooled by continuous air flow.

Efficiency. A special ceramic ensures optimal utilization of infrared light.

Air-Shield. An air Shield protects the module against the ingress of dust particles and ensures fast removal of moisture escaping from the drying materials.

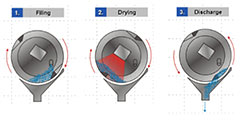

Discontinuous. Batch.

Ideal solution for thermal treatment of single batches.

Filling. The complete batch is emptied into the rotary drum.

Mixing. Thermal treatment. By rotation of the drum the material is mixed by various mixing elements, optimized to your product. The material is thereby thermally treated.

Discharging. The thermal treatment is completed after a defined period or after a specified required temperature is reached. For discharge, the direction of rotation of the drum is reversed. Thus the material flows under the gill-like main mixing elements and is fed into the outlet funnel.

Advantages for your process.

Low energy consumption. Significantly lower energy consumption compared to conventional processes, through the direct introduction of infrared energy to the product.

Minutes instead of hours. The product remains for only a few minutes in the drying process and is then available for further production steps.

Instantly. The production run can start immediately upon startup. A warm-up phase of the machine is not required.

High efficiency. The energy is immediately brought into the core of the product.

Gently. The material is heated gently from the inside to the outside and not loaded from the outside for hours with heat, and thereby possibly damaged.

Easy cleaning. Good access to all components allows for easy and fast cleaning. Rapid product change-over.

In one step. Crystallization and drying in one step.

Increased throughput. Increase of plant throughput by means of reduced load on extruder.

Evenly. Ensures a constant discharge.

Continuously.

Ideal for continuous production. Production without interruption.

Filling. By means of volumetric dosing, the material to be processed is conveyed continuously through the rotating drum.

Conveying. Mixing. Thermal treatment. A spiral welded into the rotary drum ensures a mixture of material and continuous transfer to the outlet. The material is thus thermally treated continuously.

Outlet. In minutes instead of hours, the material automatically leaves the rotary drum and can be transferred directly to the next processing step.