Turn-key solutions for food

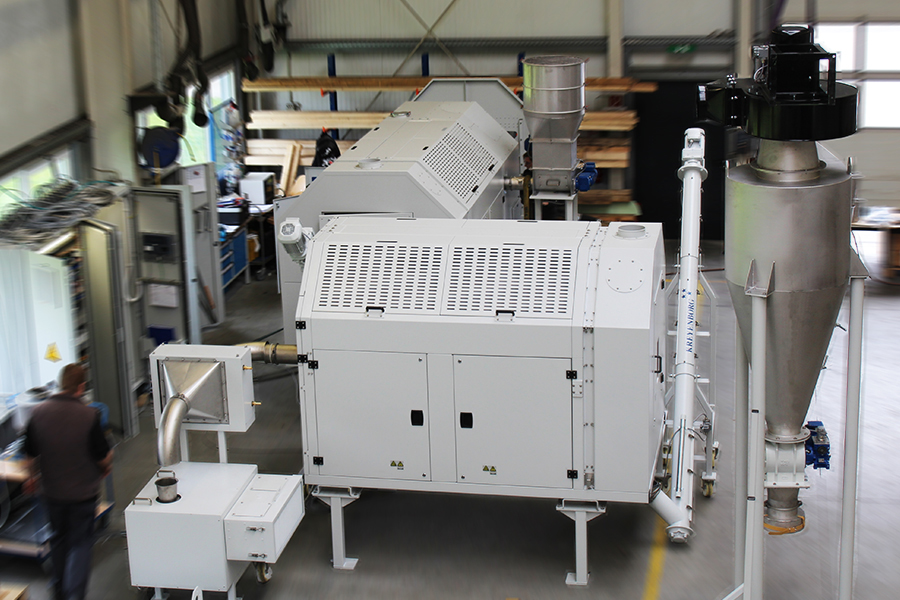

Project: Sterilization of grainy food.

Product: Granular food products.

The material was conveyed from big-bags to the doser of the FoodSafety-IRD via suction conveying. In the FoodSafety-IRD the material was sterilized and next was cooled in the cooling unit. After the cooling the material was conveyed and then filled into big-bags. The entire system was controlled by a remote control panel with touch panel and recipe management.

In addition to the sterilization, the raw food material was stock-protected.

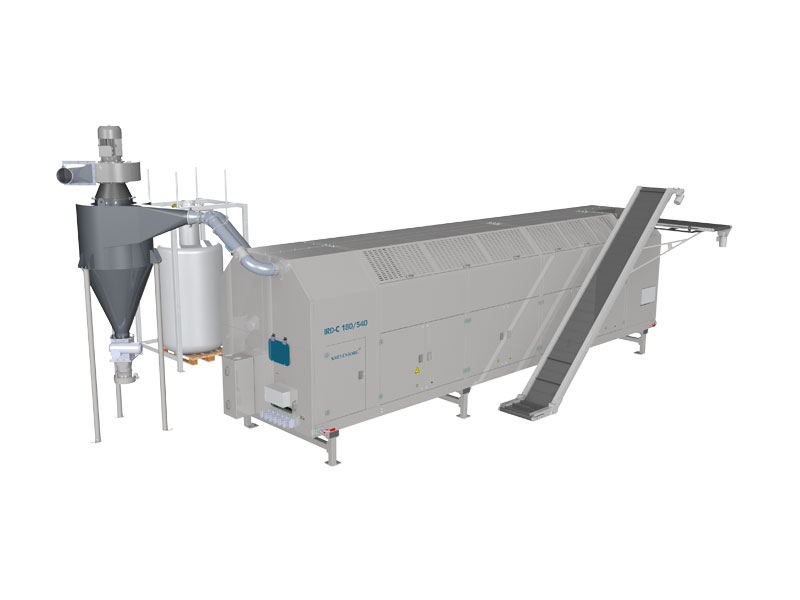

Project: Disinsectization of cereals.

Product: Cereals.

Various types of organic cereals were disinsectized and stock-protected. The conventional processes involve high costs, don’t operate continuously and don’t meet the same health standards. For these reasons, among others, the customer decided on the FoodSafety-IRD.

A FoodSafety-IRD was supplied, including dosing and control. After delivery of the organic grain, the customer started directly with the disinsectization. The organic cereal was transported by means of conveying and dosaging into the FoodSafety-IRD. Weevil and spawners were safely killed by means of infrared light. Directly thereafter, the organic grain was stored. This whole process runs automatically and continuously. The costly preparation and follow-up phases of conventional processing are omitted.

Project: Subsequent drying of foodstuff.

Product: Leaves.

For this project, a conventional belt dryer had already been installed. The aim of the customers was to increase throughput sustainably. An extension with a further belt dryer would mean a large investment for the customer. The high price for a belt dryer, possible expansion the plant, the enormous energy consumption of the belt dryer and uneven drying results were critical points in the investment considerations of the customer. Ultimately, the customer opted for the FoodSafety-IRD.

The existing belt dryer was still used to dry the leaves to a certain residual moisture. But that moisture level was significantly above the target. After the belt dryer, the leaves were conveyed to the FoodSafety-IRD. There, the material was heated via infrared light from the inside to the outside. The material was continuously conveyed and constantly mixed (the material is always in motion). In about 15 minutes residence time, the leaves lost approx. 15% moisture. Afterwards the leaves were run through a cooling unit before packaging.

The main advantages of the FoodSafety-IRD compared with a further investment in a belt dryer were the lower purchase price, significantly less space requirements, lower energy costs, and constant movement and thus mixing of the material in the drying process. This mixing yielded even drying results, because formation of nests thus did not occur.

Project: Sterilization of grainy food.

Simultaneous spraying of salt water.

Product: Granular food products.

The customer had received granular food from different sources. The qualities and purity levels varied substantially, in some cases.. Sterilizing of the material thus became essential, otherwise compliance with respective limits could not be ensured.

The special feature of this project was the combination of sterilizing and simultaneous spraying of saline water, to give the product a slightly salty taste.

After screening and cleaning, the material was constantly dosed into the FoodSaftey-IRD.

Inside the FoodSaftey-IRD, the material was continuously conveyed and treated concurrently with infrared light. The saline water was introduced during the process, lending a salty taste to the product. In the subsequent cooling unit, the material was cooled and conveyed for further processing steps.

Your possibilities.

Application examples of our products: