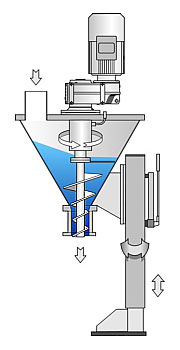

Extruder feeding system. Densifier. KSW type.

The Densifier KSW type is used for extruders with not-optimally-free-flowing products such as ground material, punching ribbon, powder, agglomerates, film flakes and fibers.

Filling level. The filling level of the KSW is monitored with a level-indicator.

Loosening. If necessary, the material is loosened up in the bin by means of special agitators and scrapers.

Pre-compaction. The material is pre-compacted via the densifiying screw.

Extruder feeding system. The compaction of the material via densifiying screw and the feeding of the extruder with constant pressure ensures optimal loading of the extruder with material.

Throughput. 100 – 4.000 kg/h (film flakes).

200 – 9.000 kg/h (powder).

Options.

Lifting system. The densifiers may be equipped with a hydraulically-operated lifting system with manually-operated pump. This device ensures the quick and easy lifting and swinging away of the aggregates from the extruder for easier cleaning and maintenance.

Coating. Special coatings of the bin and of the densifying screw for products that tend to stick.